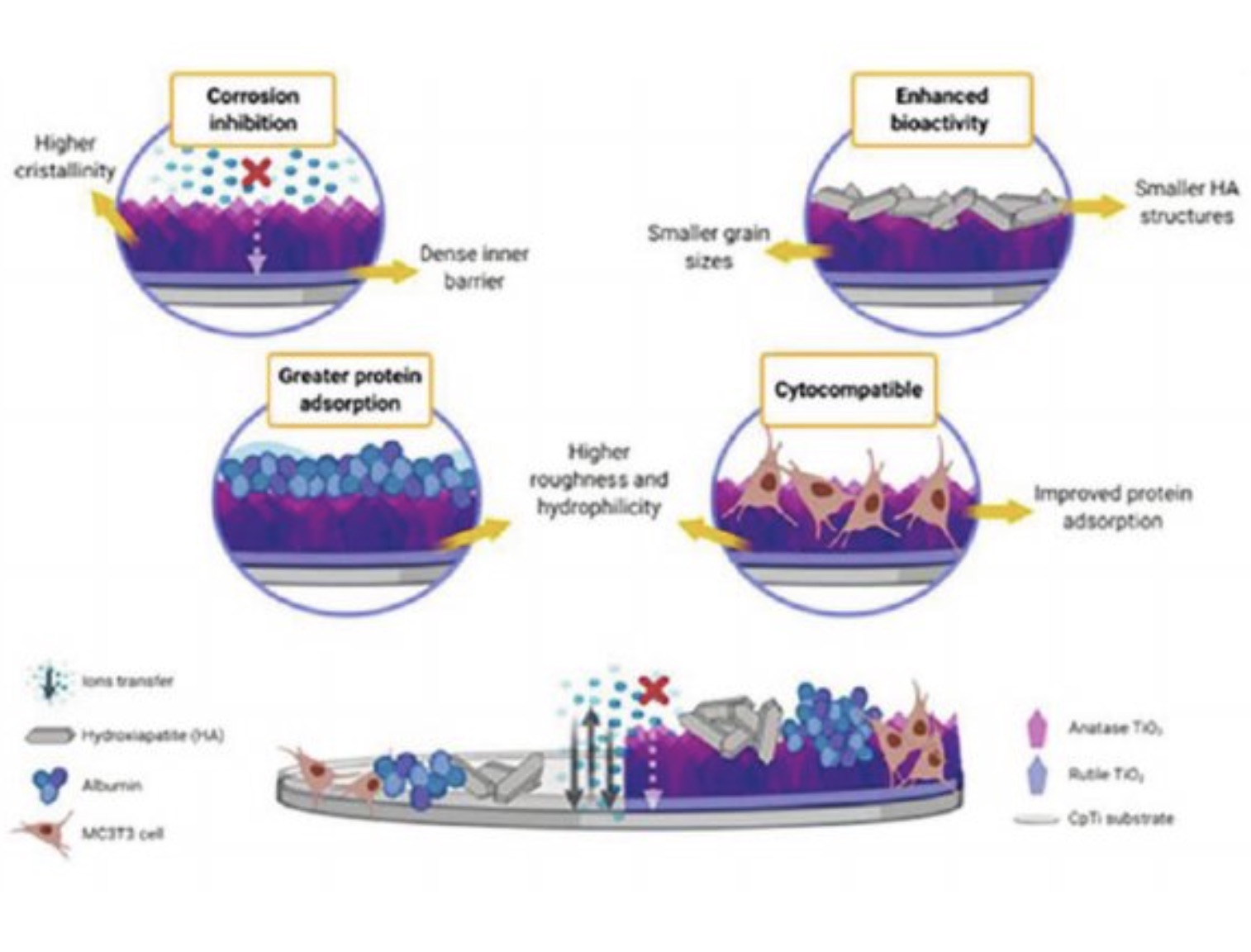

Magnetron Sputtering for Surface Engineering of Biomaterials

Dr. Megha Agrawal and Dr. Shyamasri Biswas

Founded in January 13, 2009, Intellivation marks 15 years of excellence in equipment engineering and manufacturing. Originally established in Tucson, Arizona, and then relocated to Colorado in 2012, Intellivation now operates in a >50,000 ft2 purpose-built facility dedicated to manufacturing and building state of the art vacuum deposition equipment. Recent expansions of both the facility and the team were necessary to support customers’ needs in the growing technology areas Intellivation serves. As a vertically integrated original equipment manufacturer, we offer the unique ability to design, manufacture, assemble, and commission complete systems in-house.

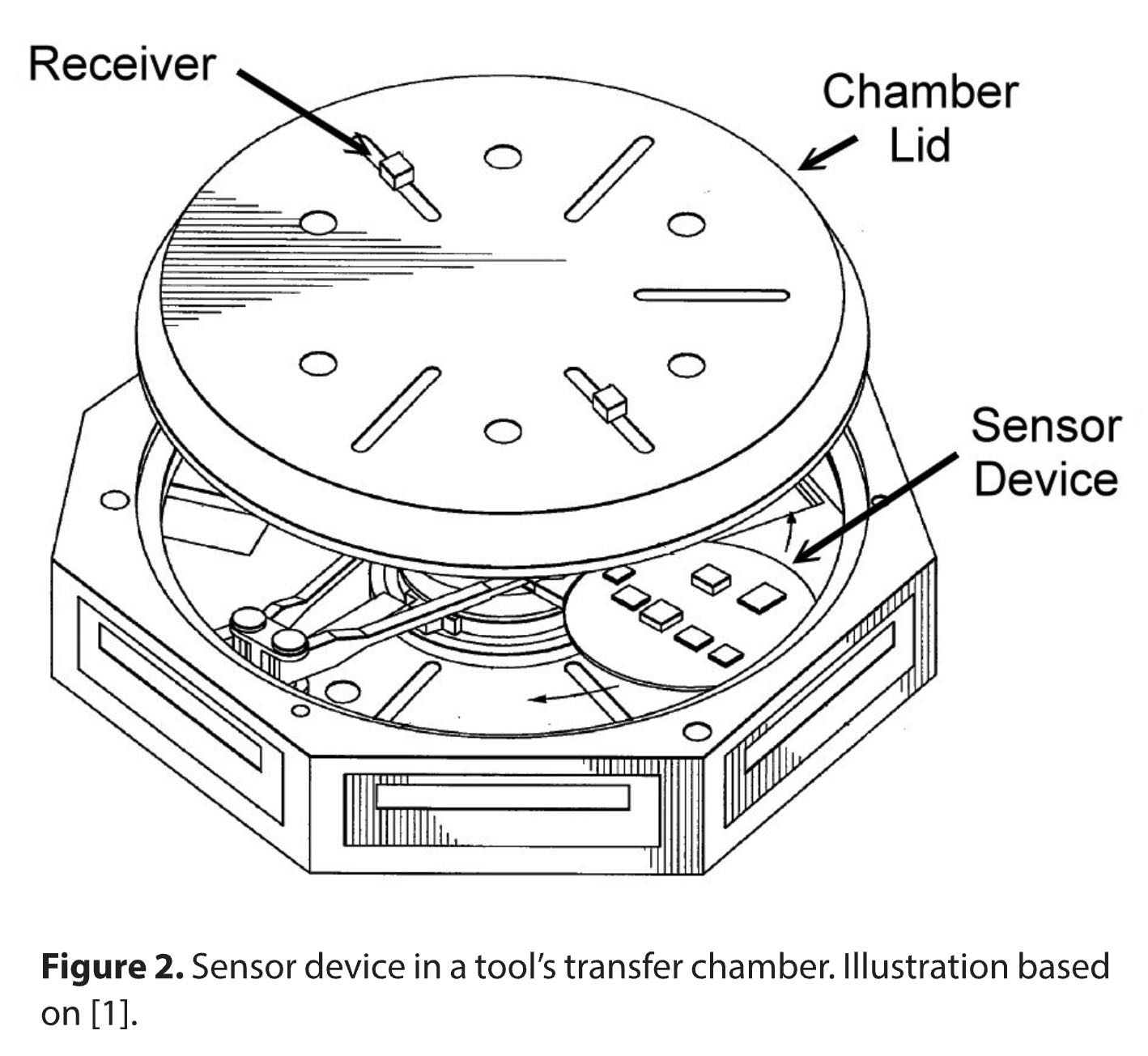

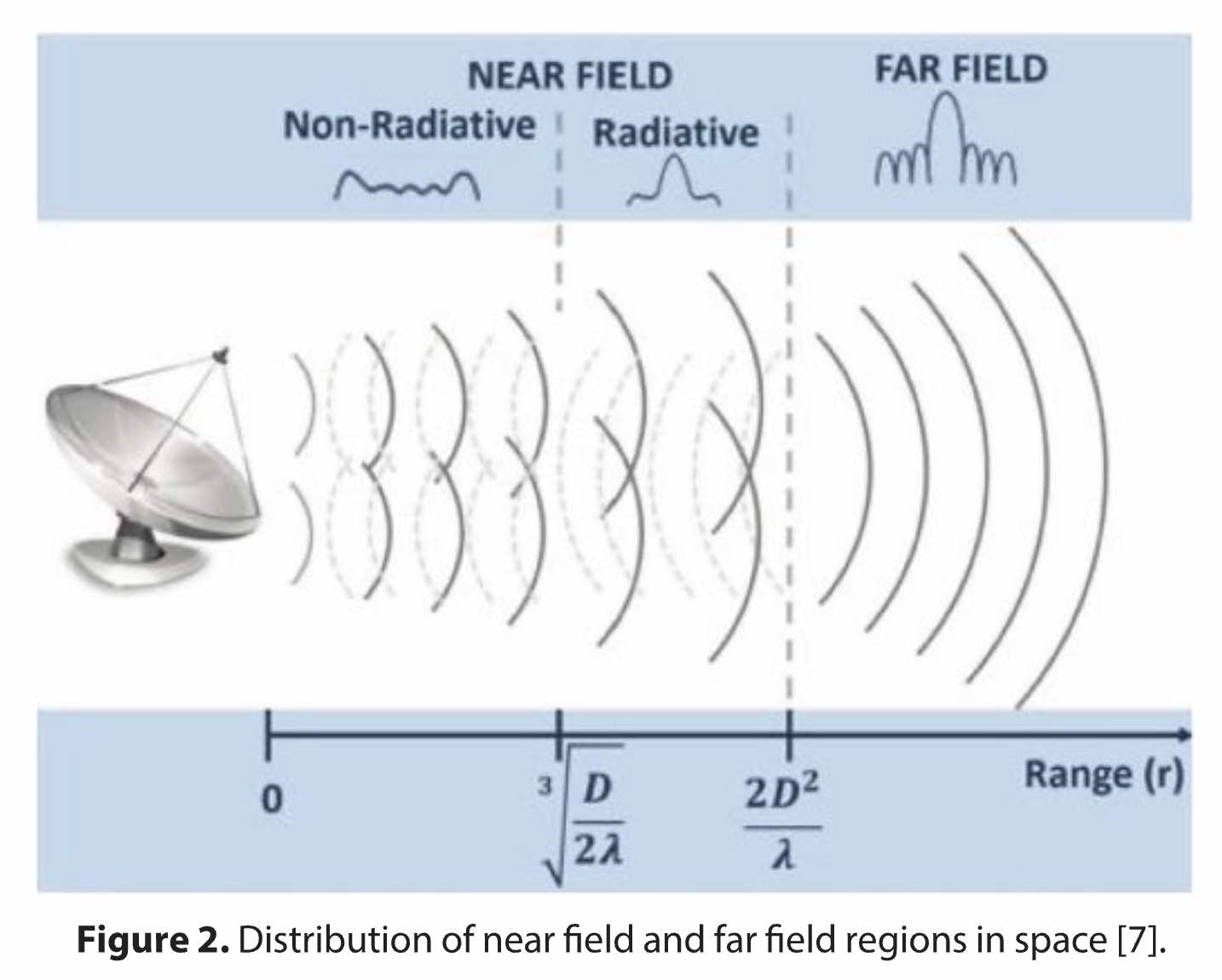

The increasing interconnectedness of sensors, controllers, and actuators in modern manufacturing presents significant challenges for communications equipment and protocols. The EtherCAT® communication protocol was developed to address these issues. However, long distances between the locations of sensors, actuators, etc. and the EtherCAT Master Controller/PC increases wiring complexity with concomitant increases in cost, system noise, and reduced performance. There can also be a need for additional I/Os when the EtherCAT Master is not easily scalable.

The 81000 Series Aluminum Gate Valves are designed for high vacuum applications specifically when pressure ranges approximate 1 x 10-7 mbar and bakeout temperatures do not exceed 150°C. These valves are designed for system integrators, designers and OEM’s within the Semiconductor, Solar, LED/FPD, Coating and BioPharm industries due to their robust design and low cost. They feature precision machined high strength aluminum bodies from solid 6061-T6 billet, dual quad ring long life shaft seals and high performance PEEK components.

The modular approach of Evergreen high power AC-DC power converters allows fast customization, as well as quick power scaling by stacking shelves. Intelligent, system-level command eliminates the need to communicate with and control units individually. This platform’s 38 W/in3 power density provides more power in less space, and > 95% efficiency with 0.98 power factor correction reduces utility costs and minimizes heat.

Since 2000 Vacuum Technology & Coating Magazine has been the industry's leading source for the latest articles, news, and product and service information. Below we describe some of the terms that you will find in a typical issue of VT&C.

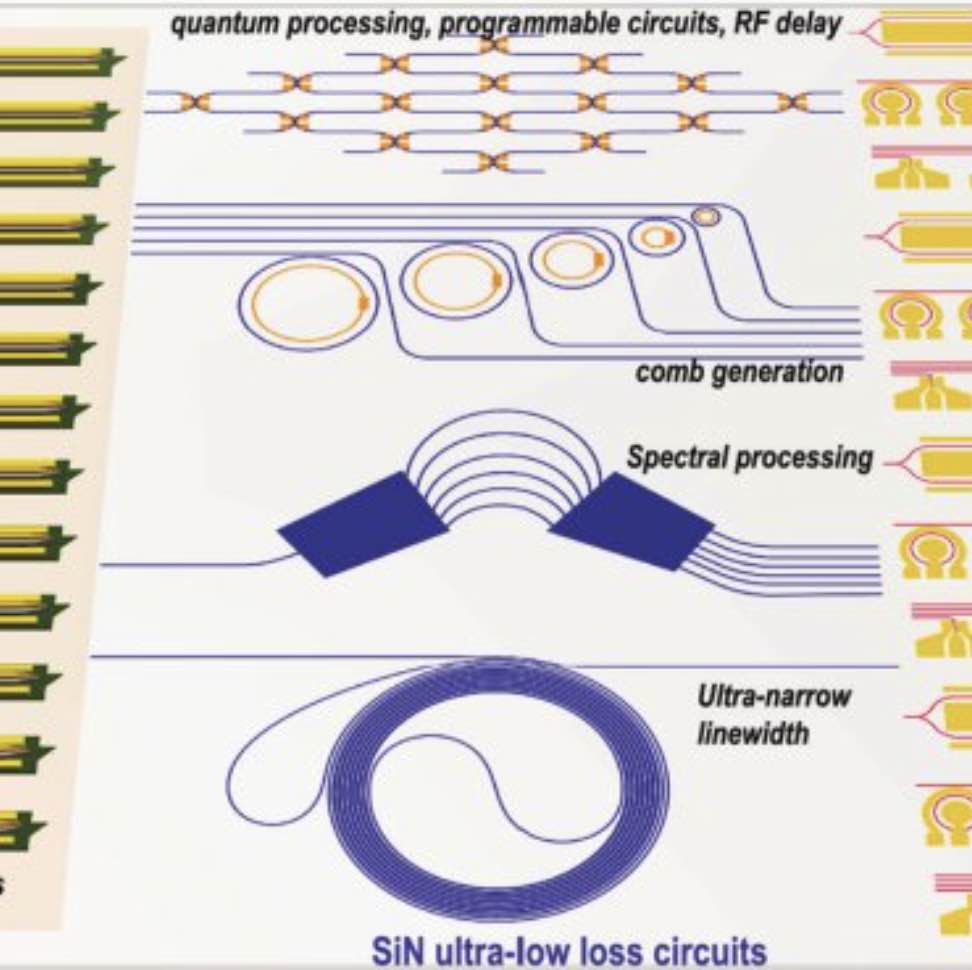

Vacuum Coating (Vacuum Deposition and Thin Film Deposition) is the process of depositing a film or other material atom by atom or molecule by molecule onto a surface in a low pressure environment or vacuum.

Physical Vapor Deposition or PVD refers to vacuum deposition methods which involve the material (which is being deposited) going from a condensed phase to a vapor phase and then to a thin film condensed phase. Sputtering and evaporation are common PVD processes.

Sputtering refers to a type of process used to deposit thin films and employs a plasma to bombard and eject atoms from a target source.

Evaporation refers to the heated source material being evaporated in a vacuum. Vacuum allows vapor particles to travel directly to the target object, where they condense back to a solid state. (called a Deposition Source) refers to a type of process used to deposit thin films and employs a plasma to bombard and eject atoms from the target source (called a Deposition Source).

Vacuum Hardware refers to the types of hardware and components that are used in the vacuum process. There are many types of hardware used in this process, some examples are flanges, fittings, seals, valves, and chambers.

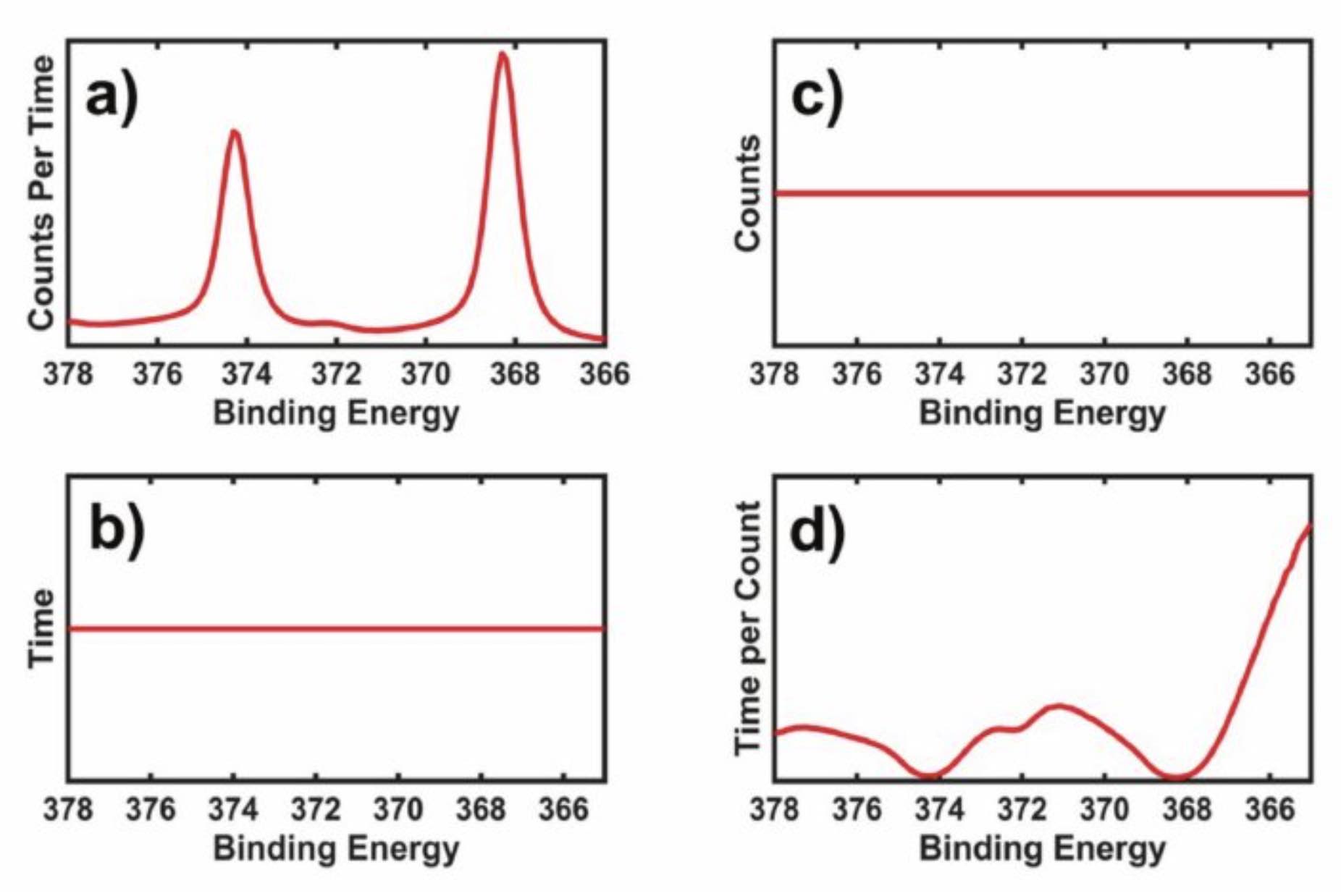

Thin Film Metrology involves determining the optimal thickness, composition and/or condition of a coating through various techniques and mathematical calculations.

Gas Analytical Systems are used in the analysis of residual gases within a low pressure environment or vacuum.

Vacuum Pumps are devices that remove gas atoms and molecules for the purpose of leaving behind a partial vacuum. Some examples of types of vacuum pumps are rotary vane pumps, diaphragm pumps, and scroll pumps.

Every issue of VT&C includes a product showcase focused on a specific topic relevant to Vacuum Processing, please see our editorial calendar which lists the topic for each issue.